HSG G3015H 12 kW

“THE LASER INVESTMENT OPENED THE DOOR TO AN ENTIRELY NEW MARKET”

When GMF Service Tingsryd AB decided to modernize its cutting process, the objective was clear: better quality, higher precision, and a more stable workflow. The result exceeded expectations. With its new HSG G3015H 12 kW from LMI AB, the company has not only streamlined its own production — it has also opened the door to a growing subcontract laser cutting market and new customer relationships.

AN ESTABLISHED INDUSTRIAL PARTNER BASED IN SMÅLAND

Founded in 1997, GMF Service Tingsryd AB has been a reliable player in welding, forging, steel structures, and industrial services for more than two decades.

With approximately 15–20 employees, its own workshop, and mobile service teams, GMF handles everything from large-scale constructions to custom-made components tailored to customer needs.

Most customers are located in the surrounding region, often within the process and wood industries, but GMF also undertakes specialized assignments throughout Sweden and the rest of Europe. Flexibility and problem-solving expertise are hallmarks of the company, making it a natural partner for both small and large projects.

THE NEED: BETTER QUALITY AND FASTER CUTTING PROCESSES

Before the investment, GMF used an older plasma cutter, which resulted in both quality challenges and time losses.

“We had uneven cut edges, a lot of post-processing, and a lower production rate than we wanted,” says Mikael Kullman.

Customer demands were increasing at the same time — particularly the need for higher precision. GMF realized they needed a solution that would deliver cleaner cuts, faster processing, and more consistent quality. The goal was also to reduce manual steps and create a workflow where settings and jobs could be managed more quickly and efficiently.

CHOOSING THE SUPPLIER: “LMI APPEARED AT EXACTLY THE RIGHT TIME”

When LMI AB made contact, GMF quickly recognized the opportunities offered by modern laser technology.

“LMI seemed professional, knowledgeable, and had the right type of machines for our needs,” says Mikael.

“It was actually perfect timing — they presented a solution that suited us immediately.”

After reviewing the alternatives, GMF chose the HSG G3015H 12 kW, a high-performance fiber laser that completely replaced the plasma cutter and delivered a dramatic improvement in quality and processing speed.

INSTALLATION AND TRAINING – A SMOOTH PROCESS

The installation was carried out in close cooperation between GMF and LMI, and according to GMF, the overall process went very well.

The only request was for additional in-depth operator training in the future — something the company sees as a next step.

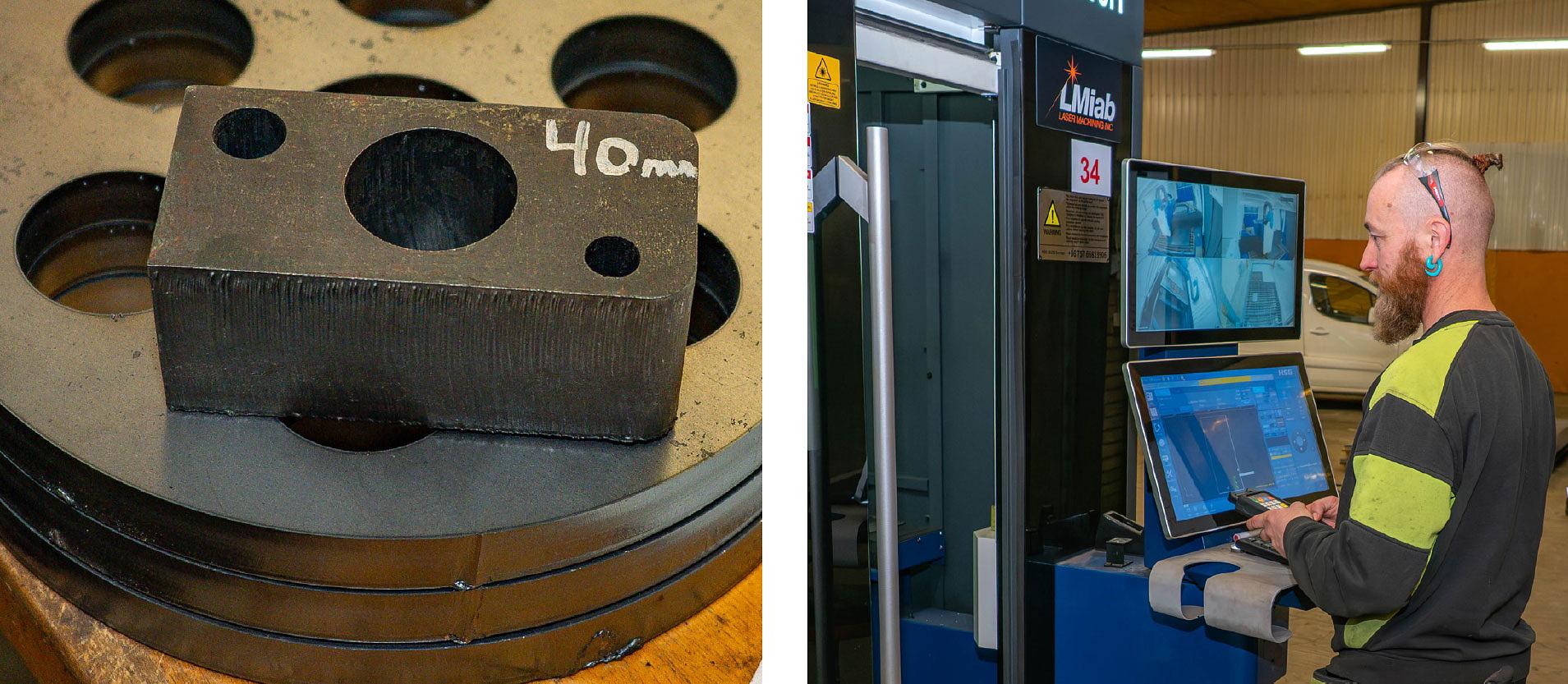

From left: Christer “Bille” Eriksson, machine operator, and Mikael Kullman, factory manager

“The installation went really well, and going forward we would like more advanced training in the software to gain even greater control over the process and parameters,”

says operator Christer “Bille” Eriksson.

“Otherwise, everything has worked very well.”

The dialogue and support have been smooth, and GMF highlights LMI’s fast response times and solution-oriented approach.

THE RESULT: FASTER PRODUCTION, HIGHER QUALITY, AND NEW CUSTOMERS

The impact of the laser investment was noticeable almost immediately. GMF now experiences:

- Significantly cleaner cut edges

- Shorter processing times

- Minimal post-processing

- Much easier job changeovers

- Higher repeatability, even in small series

It has also changed the company’s market position.

“We now have up to 25% subcontract cutting for completely new customers,” says Mikael.

“Previously, we produced almost exclusively parts for our own production. Now entirely new customers are reaching out — word spreads quickly.”

GMF can now also offer components with significantly higher precision, opening doors to new segments and business opportunities.

THE COLLABORATION WITH LMI – A PARTNER FOR THE FUTURE

GMF highlights the relationship with LMI as an important factor in their success:

- Attentiveness to company needs

- Experience in industrial laser applications

- Fast and helpful support

- Good training and clear communication

- Customized quotation and machine configuration

“We see LMI as a long-term partner. They have been with us throughout the entire process and have truly demonstrated their expertise.”

FUTURE PLANS: FURTHER STEPS TOWARD AUTOMATION

GMF is optimistic about the future and plans to continue expanding its capacity. Once workflows are further optimized, the company sees opportunities to expand the use of the laser system into additional processes, automate more production steps, and continue growing in subcontract laser cutting.

The company also signals interest in more advanced operator training and potential additions to the machine fleet.

From left: Test cutting in 40 mm mild steel with 15 mm plates beneath, and to the right, Bille preparing the machine for production.

QUOTES FROM GMF – DIRECTLY FROM PRODUCTION

“The machine from LMI has given us both better precision and significantly more efficient workflows. The quality is on an entirely different level.”

— Mikael Kullman

“We save time on almost every job — and we have also gained several completely new customers thanks to the investment.”

— Christer “Bille” Eriksson

FACTS – GMF SERVICE TINGSRYD AB

Company: GMF Service Tingsryd AB

Location: Tingsryd

Founded: 1997

Employees: 15–20

Industry: Welding, forging, steel structures, industrial services

Machine from LMI: HSG G3015H 12 kW

Installed: 2025

Impact/results: Increased precision, shorter lead times, less post-processing, higher repeatability

Website: https://gmfservice.se