Description

The ProCutter Thunder is the ideal solution for efficient and economical laser cutting in the medium power range. Whether for flatbed or 3D cutting - the cutting head plays out its advantages to the full: It offers permanently stable and precise operation. The highly dynamic drive ensures minimum non-productive times and flexibility. This controls the focus position fully automatically and delivers outstanding results when processing different material thicknesses. In addition, quick and easy maintenance of the head is possible.

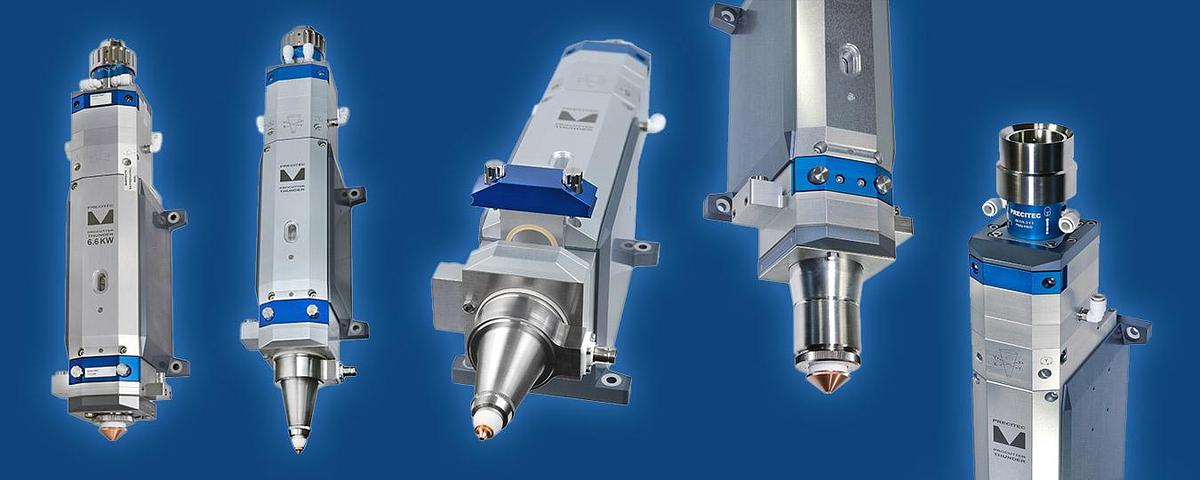

The flexible cutting head is available as a 2D and 3D version: While the 2D version is suitable for integration into flatbed, simple tube and profile cutting systems, the 3D version is ideal for use in professional tube and profile cutting systems as well as in demanding free-form applications.

YOUR ADVANTAGES AT A GLANCE

Compakt design

- High cutting speeds due to low weight

- Visual check of the focus position

Permanently excellent cutting quality

- Smooth cutting edges with minimal burrs

- Short process times

- Process-stable machining of thick materials

Low service costs and less downtime

- Easy & quick maintenance

- Protection of high-quality optics

- New monitoring via CutBox Pro

THE EQUIPMENT FEATURES AT A GLANCE

Compact design for efficient cutting

The laser optics are very robustly built, yet light and still convincing even after long periods of use.

On its front side, the set focus position can be visually checked at any time. This display also ensures simplified commissioning.

Reduced service times and costs

When maintenance of the cutting head is required, the design allows quick and easy access to the optics. A necessary change of these only requires half the time. Various protective glasses safe the valuable optics from the direction of the process zone and the fiber socket, thus significantly extending the service life.

As a new feature the ProCutter Thunder was integrated into the CutBox Pro environment that enables realtime monitoring of all sensor values.

High cutting-edge quality

The basis for smooth and right-angled cutting edges with minimal burr is the ultra-stable and drift-free distance sensor system. Even at very high accelerations, it guarantees a constant distance between the component and the head. Cooling of the head provides reproducible results in series production. Additionally, the 2D head offers additional nozzle cooling, enhancing its efficiency and ensuring optimal performance during prolonged operation.

Maximum flexibility

The ProCutter drive technology ensures minimum times for adjusting the focus position. Different thicknesses and materials can thus be cut very flexibly and at any time with high precision and stability. With higher travel distances of the focus position, it convinces as the best in its class.

Download Product Sheet

Specifications

| Manufacturer | Precitec |

| Model | ProCutter Thunder |

| Max. Laser power | 6.6 kW / 12 kW |

| Fiber sockets | 6 kW: QBH (G4.3), QD, G5 / 12 kW: QBH (G4.3), QD, Q+, LOE |

| Focal length collimation | 100 mm |

| Focal lengths focusing 2D | 3D | 150, 200 mm |

| NAmax | 0.12 |

| Vertical focus adjustment range 2D | 3D | +17.5 mm to -22.5 mm (2D | 3D) / +17.5 mm / -6 mm (100/150 | 3D) |

| Dimensions (WxDxH) | 116 mm x 113 mm x 489 mm |

| Additional Features | Protective window monitoring (optional) / Protective window monitoring Increased cooling capabilities |

| Weight | 5,6 kg |