Description

PROCUTTER 2.0 – THE BEST – MADE EVEN BETTER

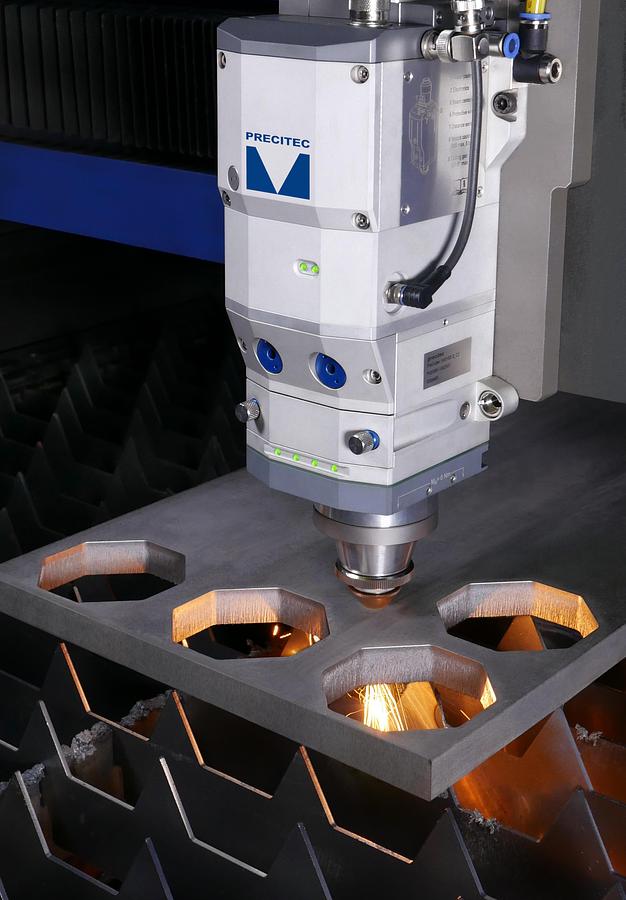

The new ProCutter 2.0 generation impresses with its increased performance and new automation features. Faster, easier, more efficient, more enduring – this is how laser cutting is shaping up in the new generation, due to numerous developments. One of the main reasons for this is the completely redesigned cutting gas flow. In addition, the reliability and power capability has been perfected – up to the maximum laser power of 85 kW. By default, the ability to exchange the nozzles automatically is now provided. The compact design is maintained, together with the extensive sensor technology, which has been specifically expanded to ensure even safer operation.

EFFICIENT - AUTOMATED - PERMANENTLY STABLE

POWERFUL CUTTING OPTICS

FOR ALL LASER SOURCES UP TO 85 KW

In laser cutting, the trend is surging towards high power, which means that significant advantages in the productivity of the cutting system and signifi-

cant cost reductions can be achieved. This includes increasing the cutting speed with thinner material thicknesses and cutting very large and thick material of more than 100 mm with an impressive cutting quality.

With the higher power, beam quality and consistency from laser to laser, among other things, experience limitations. Precitec has therefore perfected the reliable ProCutter 2.0 for 85 kW laser power. This means that the full power is available for the process. The design of the cutting head has not been changed for this purpose; it continues to be super compact, light-

weight and equally suitable for bevel cutting. The cutting head operates automatically and with long-term stability up to 85 kW laser power thanks to its sophisticated cooling concept, integrated sensors and extended adjustment range.

TECHNOLOGY PACKAGE

PIERCETEC – AUTOMATED PIERCING

PierceTec ensures fast, clean and reproducible piercing. The basis for this is an integrated sensor and a full automatic real-time control of the laser power. Typical annoyances are a thing of the past: With PierceTec, the customer enjoys short piercing times even in thick materials, consistent hole quality and high process reliability. In addition, PierceTec protects the usual wear parts – in particular the protective window on the process side and the nozzle. The occurrence of smoke and splashes is minimized. Furthermore, PierceTec monitors the subsequent cutting process and reliably detects interruptions. In short: PierceTec saves cycle time and operation costs – while increasing the performance and quality of the piercing process.

Customer Benefit

- reliable piercing process, even in continuous operation » increased operational safety

- high time savings compared to conventional piercing » increased productivity

- increased service life of wearing parts and machine bed » lower operation costs

- reliable detection of cut interruption » lower waste

Specifications

| Manufacturer | Precitec |

| Model | ProCutter 2.0 |

| Max. Laser power | 8 kW / 15 – 30 kW / 40 kW / 85 kW |

| NAmax | 8 kW: 0.13 | 15-30 kW: 0.13 | 40 kW: 0.18 | 85 kW: 0.16 |

| magnification | 8 kW: 1.25 / 1.5 / 1.75 / 2.0 | 15-30 kW: 1.5 / 2.0 / 2.5 / 3.0 | 40 kW: 2.1 / 2.4 / 3.0 / 3.6 | 85 kW: 3.0 |

| Dimensions (WxD) | 8 kW: 96 x 134 mm | 15-30 kW: 96 x 134 mm | 40 kW: 96 x 134 mm | 85 kW: 96 x 134 mm |

| Axial length | 8 kW: 313 mm (M 1.25) | 15-30 kW: 363 mm (M 1.5) | 40 kW: 368 mm (M 2.1) | 85 kW: 469 mm |

| Weight | 8 kW: 6.2 kg (M 1.25) | 15-30 kW: 6.3 kg (M 1.5) | 40 kW: 6.5 kg (M 2.1) | 85 kW: 6.9 kg |

| vertical adjustment range 8 kW | + 6 / - 9 mm (M 1.25) |+ 9 / -13 mm (M 1.5) | +12 / -18 mm (M 1.75) | +15 / -20 mm (M 2.0) |

| vertical adjustment range 15-30 kW | +10 / -16 mm (M 1.5. 15 kW) |+15 / -30 mm (M 2.0. 15 kW) | +25 / -30 mm (M 2.0. 20 kW) | +28 / -38 mm (M 2.5. 30 kW) | +33 / -66 mm (M 3.0. 30 kW) |

| vertical adjustment range 40 kW | +25 / -30 mm (M 2.1) | +25 / -54 mm (M 2.4) | +33 / -66 mm (M 3.0) | +33 / -66 mm (M 3.6) |

| vertical adjustment range 85 kW | +45 / -91 mm (M 3.0) |