Description

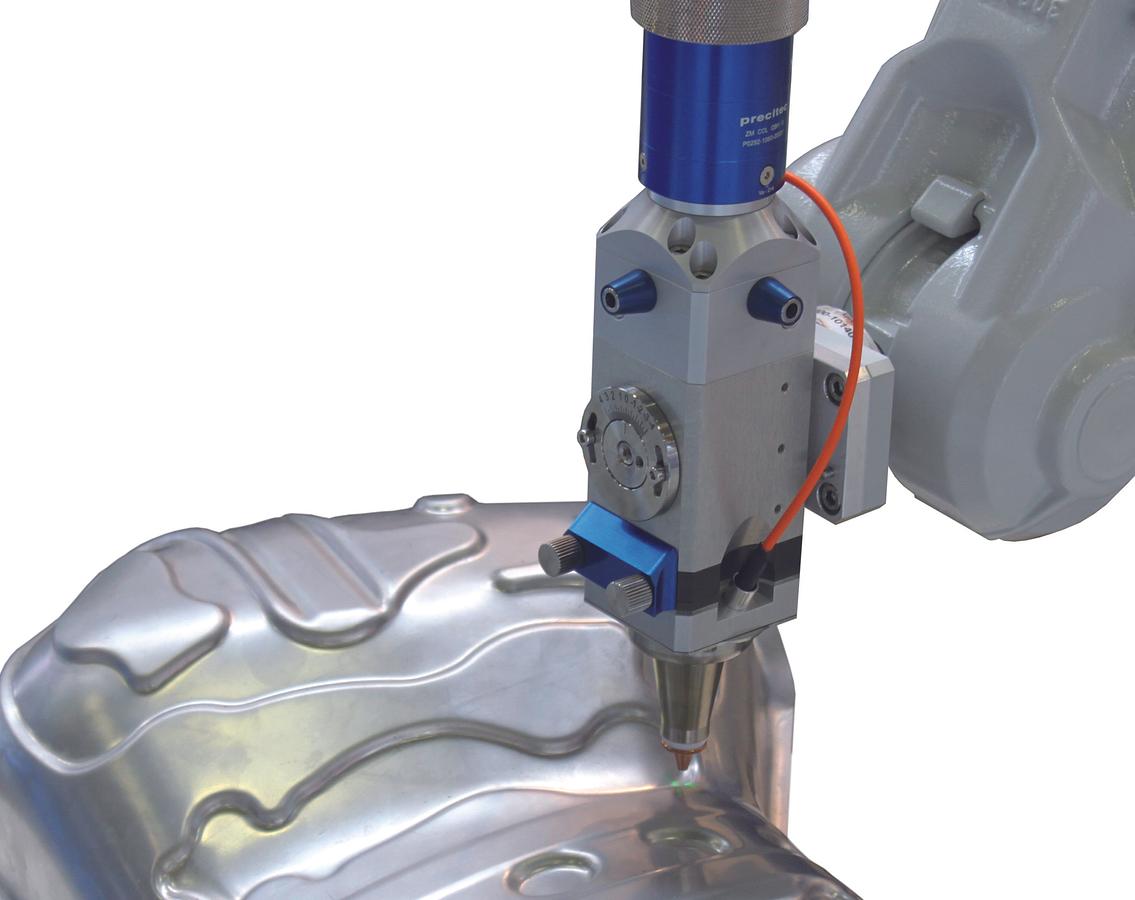

The MiniCutter is a real all-round talent. It is compact, light and cuts thin metals efficiently and cheaply with fiber guided laser of up to 4 kW.

The fast-reaction distance control system guarantees a constant cutting quality particularly when cutting complexes shapes. The slim design enables a high accessibility for cutting strongly curved parts. But not only in robotic applications the processing head has many advantages. Also in flatbed cutting the MiniCutter 2D is working very well thanks to the compact shape of the sensor insert.

For reliable operation both cutting heads versions are protected from melt splatter, metallic fumes and cutting gas by a protective window. The focal position can be adjusted from outside in a lateral and vertical position.

Efficient

- excellent value for money

- simple and rapid changing of protective window cartridge (no tools required)

- sophisticated design of mechanical components

Flexible

- focal lengths can be adapted perfectly to the application

- Plug & Play system

- Adaption to customized Z-axis possible

User friendly & Safe

- temperature stable distance control

- sealed beam path

- scale for setting the focal position in lateral and vertical direction from outside

- high-quality optics

- slim and sturdy design

Download Product Sheet

Specifications

| Manufacturer | Precitec |

| Model | MiniCutter 2D & 3D |

| Max. Laser power | 4 kW (for wavelengths of 1030 – 1090 nm) |

| NAmax 2D | 0.13 @ FC75 (MiniCutter 2D: fokuseringslinser 100 mm, 125 mm) |

| NAmax 3D | 0.13 @ FC75 |

| Dimensions (WxDxH) | 50 x 50 x 258 mm (FF75), 50 x 50 x 283 mm (FF100), 50 x 50 x 303 mm (FF125), 50 x 50 x 328 mm (FF150) |

| Weight | 1,4 kg |

| Vertical adjustment range | ±4 mm |

| Max. cutting gas pressure | 20 bar |